Disclaimer: You may or may not agree with these views. I originally wrote this opinion article in response to a question about how I felt what direction building codes and standards should be heading in the future. If this bothers you, tell me why. If you agree, tell me why. Mature, educated individuals debate these topics for a reason; to agree on the best solution to a problem or situation. Without productive discourse, our society does not advance.

Changing the way building codes are written or enforced is only a symptomatic treatment for the larger underlying cause of industry frustration. The real culprit is a disturbing lack of competence, training, experience, or sense of responsibility in those who either must comply with or enforce local, state and national codes for building and life safety.

I have been in the design and construction industry for over 20 years, and a licensed architect since 2004. I’ve worked in small and large architectural firms from Washington to Florida, and on my own as a sole proprietor. I’ve worked in construction; with at least some experience in nearly every trade category on both residential and commercial projects. I was a state and federal surveyor, inspecting long‐term care facilities including nursing homes, assisted living facilities, adult daycare and intermediate care facilities for those with intellectual disabilities. I inspected facilities for compliance with licensing rules and nearly 100 different national codes and standards. I have worked alongside and opposite of architects, engineers, contractors, sub‐contractors, owners, operators, developers, city officials, inspectors and the end‐users and occupants of hundreds of buildings. Over the last eight to ten years, I have focused a great deal of my professional time on learning and teaching others across the industry how to comply with adopted codes and standards. I have been nicknamed a “code geek”; a label I’m proud to wear.

In that time, building codes, testing procedures and products have become more complex, and at times more difficult, to understand. A very large percentage of architects, engineers and contractors frequently complain about building codes getting out of control or various authorities overstepping their jurisdiction. While I believe there are changes that can be made to how codes are written and structured, the real solution lies with the individual whose responsibility it is to protect the health, safety and welfare of the public; the architect.

Architects are responsible for knowing and coordinating a tremendous amount of technical information, while listening to the needs of their clients and creating something functional, pleasing to be in, healthy and safe. It’s that last requirement that eludes so many architects; safety. This concept would include nearly every chapter and requirement in most building or life safety codes. I can somewhat forgive, or at least understand, a general contractor’s lack of code knowledge or understanding, but architects in the United States are held to a higher standard just by the mere fact they are licensed, educated and trained professionals. Every architect has the ability and the obligation to create the safest environment they can. The disturbing reality is that code compliance and thoughts of building occupant safety are left to the end of a project as an afterthought and then treated as a hindrance to good design rather than its single most important aspect.

The lack of knowledge in codes and life safety systems by today’s architects is due to inadequate education, little to no post‐education training, and very little sense of urgency by those licensed to practice architecture.

Education, or a lack thereof, is where the issue begins. Although not every architect is a member of the American Institute of Architects (AIA), most state licensing laws emulate the AIA’s basic code of ethics and standards of professional practice. The AIA defines the concepts of Health, Safety and Welfare (HSW) in The Architect’s Handbook of Professional Practice as:

Health: Aspects of architecture that have beneficial or salutary effects on occupants and users of buildings or sites and address environmental concerns.

Safety: Aspects of architecture intended to limit or prevent accidental injury or death of occupants and users of buildings or sites.

Welfare: Aspects of architecture that engender demonstrable positive emotional responses from, or enable equal access by, users of buildings or sites.

AIA’s Continuing Education System (CES) HSW courses fall within nine different categories, three of which mention safety or safety related topics:

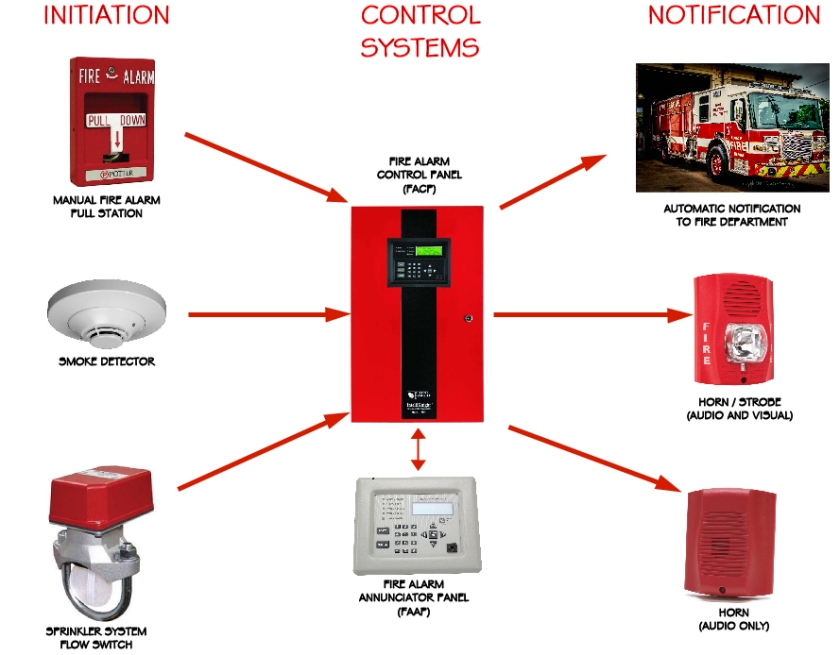

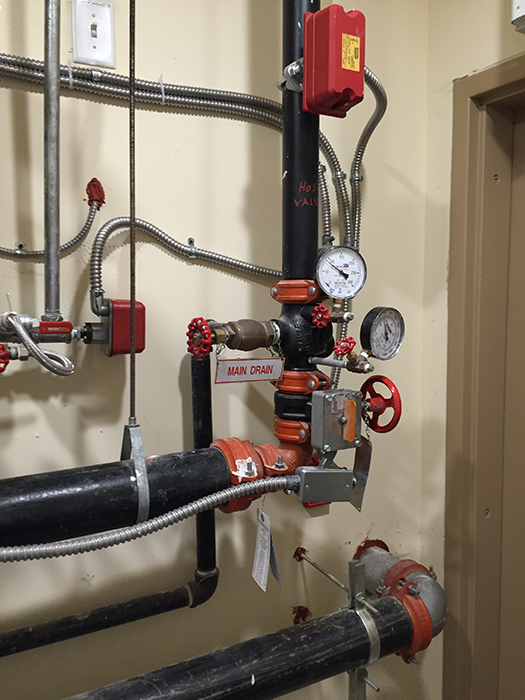

Building systems: Structural, mechanical, electrical, plumbing, communications, lighting, acoustics, egress, security and fire protection

Design: Urban planning, master planning, building design, site design, interiors, safety and security measures

Legal: Laws, codes, zoning, regulations, standards, life safety, accessibility, ethics and insurance to protect owners and the public (from AIA.org)

Considering safety and security is mentioned in at least one third of continuing education categories and is one of the most important aspects of our profession, it stands to reason that a substantial amount of time should be spent by every licensed architect in attaining the knowledge needed to adequately protect the occupants of our buildings from harm. Sadly; this is far from the truth.

I personally graduated with my Bachelor of Architecture and Bachelor of Science in Architectural Studies from Washington State University in 1998 (Magna Cum Laude). Over 12 semesters and a total of 157 credit hours; the total number of classes dedicated in any way to codes, standards or fire protection was ONE. A single, two credit hour class that more than half of my classmates failed to pass the first time. For full disclosure, I received an ‘A’ in the class on the first try. That is only 1.2% of my total credit hours, and as any former architectural student knows; a minuscule fraction of the time spent actually studying or working in school. As of this paper, my alma mater no longer requires bachelor or master’s degree students to take the codes class I took (ARCH 472). It is now offered as an optional elective. Most university programs I have researched are no better.

The National Council of Architectural Registration Boards (NCARB), requires accredited university architectural programs to provide a minimum of three (3) hours out of 150 total toward “Laws and Regulations”. That’s two percent of the total hours in an accredited architectural program dedicated to educating architects on how to protect the safety of the general public as well as contractual obligations and other legal matters. That’s not only disturbing, it’s absurd.

The 2018 AIA Conference on Architecture in New York City offered more than 650 sessions on a wide variety of topics affecting architectural practice today, including several on resilience and designing with natural hazards in mind. Out of 650 sessions, I could identify only one that was devoted to the safety of a building’s occupants from internal hazards. One single session (TH205) discussed aging buildings, the jurisdictional issues with renovations and the need to prevent building material collapse due to aging. This lack of continuing education opportunities appears to directly mirror the lack of emphasis on teaching building safety in our educational system.

If the initial and continuing educational systems set in place do not emphasize (and follow through) on building and occupant safety, then where does that experience and knowledge come from? At the moment, it comes from professional organizations that publish the various model codes and standards adopted across the country. The International Code Council (ICC) and the National Fire Protection Association (NFPA), are the premier organizations in the United States that emphasize life safety and fire protection / prevention as a critical priority. A small percentage of the individuals who belong to or work with these organizations are licensed architects. A significant amount of participation comes from public jurisdictions such as city and state governments, first responders like fire fighters and paramedics, building officials, inspectors and other individuals whose entire career revolves around public safety.

This is where the disconnect between Architects, building codes and code enforcement begins to get worse. The vast majority of Architects I have met and/or worked with do not understand the most basic of building code issues; What is a building code and how is it created and enforced? The fact that a jurisdiction’s building code is actually enacted by law, and only subject to official interpretation by the jurisdiction that has passed that law, seems to elude even the most senior architects. This lack of understanding leads to an immediate adversarial relationship between the architect (required by their license to protect public safety), and a local city government for example (required by law to protect the safety of its residents). Both sides are supposed to have the same end goal, and the code is a set of rules and procedures to ensure both sides have done their best to ensure the safety of the public. I do have to acknowledge that many of these issues go both ways though, as public sector employees with no formal training or experience in design and construction can cause identical problems. The same lessons can be applied to both sides.

As an architect progresses in their career, the knowledge and expertise needed to design safe and code compliant buildings should increase. The lack of initial knowledge and inadequate continuing education, training or even discourse among architects on this subject leads to the current frustration over the codes themselves. Any person, organization or interest group that has not spent a large percentage of their time devoted to building safety cannot adequately effect change on the way codes are written without first changing the system that caused the issue.

The prime focus for any group of Architects that is looking to make a positive impact on today’s codes and standards should be education and training first.

‐Shawn Gillen, AIA

Vice President, DFD Architects